Roller Conveyor Systems

Roller Conveyor Systems for Efficient Material Handling

A Roller Conveyor System is a vital material handling solution designed to transport goods smoothly and efficiently within industrial environments.

From lightweight cartons to heavy pallets, roller conveyors provide reliable and controlled product flow across warehouses, factories, and logistics facilities.

Talk to our experts and build the right solution for your industry.

Inquiry NowHow Roller Conveyor Systems Operate

Roller conveyors function by allowing products to move over rotating rollers, either through gravity or powered mechanisms.

Working Principle

- Products move across rollers positioned at uniform intervals

- Gravity conveyors use incline movement without power

- Powered conveyors use motors for controlled speeds

- Bearings reduce friction and ensure smooth motion

- Curved sections guide materials around bends

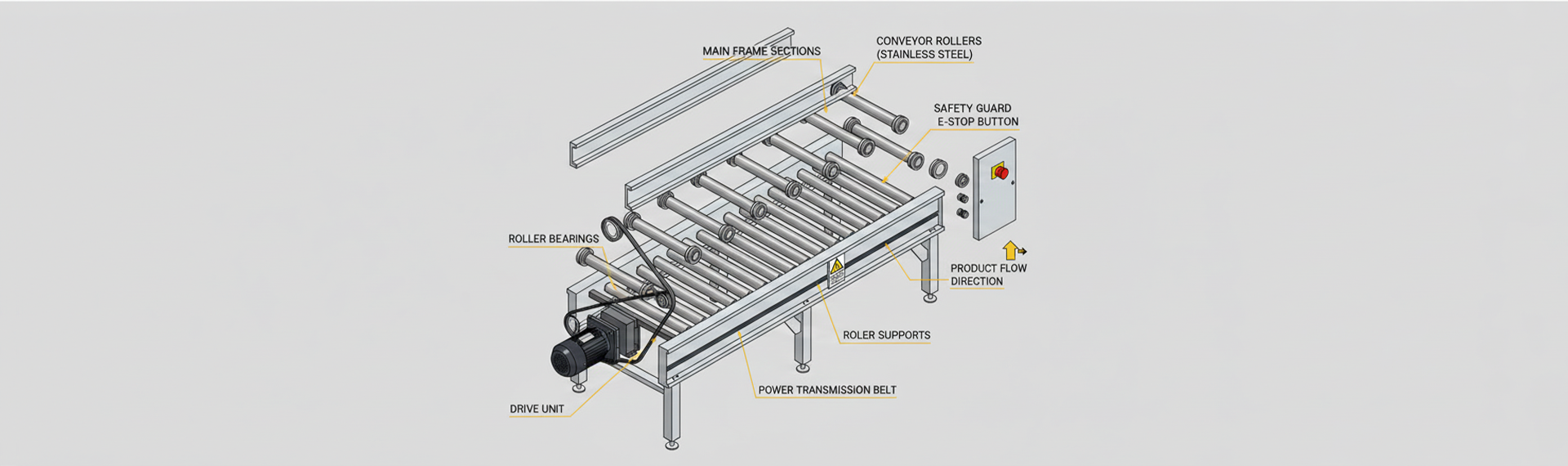

Core Elements of a Roller Conveyor

- Conveyor Rollers – Steel, aluminum, or polymer rollers for smooth transport

- Structural Frame – Heavy-duty frame for load support

- Adjustable Support Stands – Height-adjustable legs

- Drive System – Motors, chains, belts, or shafts

- Bearings & Housings – Reduce wear and increase lifespan

- Directional Rollers – Enable smooth curved movement

Types of Roller Conveyors

- Gravity Roller Conveyors – Economical and energy efficient

- Powered Roller Conveyors – Automated and controlled movement

- Chain-Driven Roller Conveyors – Heavy-duty industrial applications

Industrial Advantages of Roller Conveyors

- Improved productivity with reduced labor

- Space optimization with straight and curved layouts

- Enhanced operational safety

- Low energy consumption

- Custom-engineered sizes and capacities

- Long service life with durable components

Roller Conveyor Maintenance & Support by Trimech India

Trimech India provides expert maintenance and support services to ensure roller conveyor systems operate at peak efficiency. Our preventive maintenance approach minimizes downtime, improves reliability, and extends the service life of conveyor equipment.

Our Maintenance Approach

- Inspection of rollers, shafts, and bearings

- Lubrication of drive and moving components

- Cleaning of conveyor surfaces to prevent jams

- Correction of misalignment and vibration issues

- Performance checks under actual operating conditions

For conveyors operating in harsh or continuous-duty environments, we design customized maintenance schedules that protect motors, bearings, and mechanical components from excessive wear and stress.

Need a Conveyor System Built for Your Operation?

Connect with Trimech India to get a roller conveyor solution tailored to your workflow, load requirements, and facility layout.